Description

The Currie HD60 high-pinion front axle for the 2018 and newer Wrangler JL delivers next-level strength and reliability. The HD60 features a massively reinforced rotated 60 series center section, 3.5-inch tubes, chromoly axles, and heavy-duty forged JL inner knuckles. Upgrade to an HD60 and start enjoying your off-road adventures without the worry of frontend failure.

The HD60 high-pinion axle for the 2018 and newer Jeep Wrangler JL features heavy-duty brackets and mounts in the stock location for a direct bolt-in fit. The vehicle's factory outer steering and brake components must be transferred to the HD60 to complete the assembly. A high-clearance aftermarket tie rod is required (see notes below). The vehicle's factory driveshaft will require modification or replacement to accommodate the larger 60 series housing and 1350 series u-joint

Details:

- 68 in. Stock JL Rubicon Width (+1.5 in. Over Non-Rubicon Models)

- HD60 High-Clearance Center Section with Rotated Cover Improves Obstacle Slide-Over

- High Volume Flow-Thru Pinion Oiling System Keeps Bearings Bathed in Cool Oil

- Rock Slider Low-Friction Skid Plate Glides Over Rocks

- 3.5 x .375-inch DOM Axle Tubes are Twice the Strength of the Stock Tubes

- Currie Chromoly 35-Spline Inner and 32-Spline JL Outer Axles

- Currie Heavy-Duty Forged JL Inner Knuckles

- Choice of Selectable Locker and Gear Ratio

- Currie Heavy-Gauge Laser Cut Brackets

- Upgraded 1350 Pinion Yoke

- Currie Rock-Proof Nodular Iron Differential Cover

- Satin Black Powder Coat Finish For Long Lasting Protection

- Retains the Vehicle's Stock Outer Steering Knuckles, Brake Assemblies, and Wheels

- Requires Aftermarket High-Clearance Tie Rod Assembly (see note below)

Currie HD60 Features:

|

HD60 high-pinion nodular iron center section is simply the strongest 60 series casting we offer, with heavier main caps, ARP® main bolts, and additional reinforcement in critical areas |

|

|

HD60 high-pinion radius bottom center section delivers unmatched ground clearance, and improved obstacle slide-over by presenting a smooth curve rather than the sharp leading edge found on other 60 housings | |

|

Replaceable AR400 hardened steel skid plate resists deformation and gouging to slide over obstacles far better than iron housings or mild steel plates | |

|

Large diameter outer pinion bearing (right) is designed for the demands of reverse rotation/high pinion housings. Stock low pinion bearing (left) | |

|

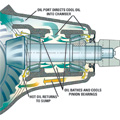

High volume flow-thru recirculating oil system keeps pinion bearings bathed in cool oil, reducing operating temperatures and eliminating oil starvation issues | |

|

Large 3.5 in diameter .375 wall axle tubes (left) are twice as strong as the factory tubes without being overweight or sacrificing ground clearance |

|

|

Upper control arm mounts feature rebuildable Johnny Joints® for maximum suspension articulation with unsurpassed durability | |

|

Super strong Currie nodular iron front cover protects expensive internals, adds structural support to the housing's face flange, and locates the driver’s side upper control arm mount | |

|

Lower control arm mounts are one-piece construction with integrated skid plates to help fend off bracket seeking rocks | |

|

Black satin powder coat finish adds long-lasting protection against rust and corrosion to keep your HD60 looking its best |

| Vehicle Fitment | 2018 and newer Jeep Wrangler JL |

| Housing | HD60 high-pinion nodular iron radius bottom center section with thicker walls and webbing |

| Bearing Caps | Increased cross section nodular iron caps secured with ARP® fasteners |

| Pinion Bearing | Large diameter front pinion bearing matched to rear bearing |

| Pinion Oiling | High volume flow-thru recirculating oil system |

| Gear Set | Dana 60™ reverse rotation thick gear sets (compatible with super 60 reverse cut gears) |

| Differential Carrier | Standard Dana 60 4.10 and down differential carriers with thick ring gears for all gear ratios |

| Pinion Yoke | 1350 u-joint |

| Skid Plate | AR400 hardened steel skid plate |

| Differential Cover | Currie nodular-iron cover, Red |

| Axle Tubes | 3 .5 inch diameter x .375 wall DOM tube |

| Axles | Currie Chromoly 35-Spline Inner and chromoly 32-Spline JL Outer Axles |

| End Forgings | Currie JL/JT heavy-duty forged steel inner C’s |

| Steering Knuckles | Accepts the vehicle's factory steering knuckles |

| Brake Rotors | Accepts the vehicle's factory front rotors |

| Brake Calipers | Accepts the vehicle's factory front calipers |

| Tie Rod | Accepts the vehicle's factory tie rod |

| Suspension Brackets | Heavy gauge 3/16 inch steel mounting brackets |

| Control Arm Mounts | Johnny Joints® installed with greaseable bolt |

| Geometry | Optimized for stock height up to 4 inch of lift |

| Trac Bar Mount | Ram mounting brackets welded to housing, setup for PSC 8” travel steering ram (not compatible with stock steering stabilizer) |

| Width | 68-inch stock Wrangler JL Rubicon width (1.5 inches wider overall than non-Rubicon models) |

| Finish | Black satin powder coat |

NOTES:

Tie Rod: The HD60 housing requires the use of a high-clearance aftermanket tie rod to prevent tie rod/housing interference at full turn. JL Rubicon/JT compatible high-clearance tie rods are available from Steer Smarts (Yeti XD P/N 78088001)

ABS Sensors: This does not include ABS sensors, the factory sensors from the stock axle must be retained and installed on the Currie housing

Computer Programming: Vehicles require a computer programmer to reset the gear ratio and tire height in the vehicle's computer for the proper function of the vehicles stability control and transmission shift points

Steering Stabilizer: The HD60 Ram assist bracket requires an aftermarket stud style trac bar bolt to accommodate a steering stabilizer. Trac bar bolts are available from FOX Racing P/N 803-02-028 or Synergy Manufacturing P/N 8806-01