Description

The Currie Extreme 60 front and rear axle set for the Jeep Gladiator Truck, is designed for severe off-road use with tires up to 40-inches and V8 horsepower. The high-pinion design features Currie's exclusive rotated center section with ring gear load-bolt, a combination that delivers superior obstacle slide-over and unmatched gear strength. If you seek out the most challenging routes and toughest obstacles to conquer, the Extreme 60 axle set is a natural choice.

The Extreme 60 high-pinion axle set for the 2020 and newer Jeep Gladiator, includes complete bolt-in front and rear axle assemblies with all required brackets and mounts in place. The vehicle's factory driveshafts will require modification or replacement to accommodate the larger 1350 series u-joint and 60 series housing

Axle Set Details:

- Fully Assembled Extreme 60 High-Pinion Front and Rear Axle Assemblies

- 70-72.5-Inch Width Provides Improved Clearance for Large Tires

- 8-Lug Wheel Bolt Pattern for Ultimate Reliability

- Satin Black Powder Coat Finish for Long Lasting Protection

- Choice of Selectable Locker and Gear Ratio

Exclusive Extreme 60 Features:

- High-Clearance Center Section with Rotated Cover Improves Obstacle Slide-Over

- High-Pinion Design Raises the Driveshaft by 2-Inches for Additional Clearance

- Ring Gear Load Bolt Prevents Deflection to Deliver Maximum High-Pinion Gear Strength

- High Volume Flow-Thru Pinion Oiling System Keeps Bearings Bathed in Cool Oil

- Rock Slider Low-Friction Skid Plate Sides Over Trail Obstacles with Ease

Extreme 60 Axle Features

|

||

|

Extreme 60 high-pinion nodular iron center section is the strongest 60 series casting we offer, with heavier main caps, ARP® main bolts, more reinforcement in critical areas over the already strong Currie 60 center | |

|

Ring gear load bolt (top left) eliminates gear deflection, to dramatically increase torque handling capacity. The load bolt typically sits .002 inch from the ring gear and only touches when extremely high torque loads are applied | |

|

Extreme 60 high-pinion radius bottom center section delivers unmatched ground clearance, and improved obstacle slide-over by presenting a smooth curve rather than the sharp edge found on other 60 housings | |

|

Replaceable AR400 hardened steel skid plate resists deformation and gouging to slide over obstacles far better than iron housings or mild steel plates | |

|

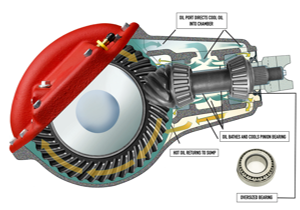

High volume flow-thru recirculating oil system keeps pinion bearings bathed in cool oil, reducing operating temperatures and eliminating oil starvation issues | |

|

Large 3.5-inch diameter .375 wall axle tubes (left) are more than three times stronger than the factory Dana® 44 (right) without being overweight or sacrificing ground clearance | |

|

Black satin powder coat finish adds long-lasting protection against rust and corrosion to keep your Currie Extreme 60 looking its best | |

Extreme 60 Front Features

|

||

|

Front axle steering geometry is optimized for large tires and lifted vehicles with increased caster and pinion angles | |

|

The included heavy-duty tie rod features a 1.375 in. OD x .375 wall heat-treated chromoly tube and 1-ton forged rod ends that are designed to withstand off-road abuse and large tires | |

|

Massive forged 1-ton inner knuckles (right) are designed to stand up to the severe punishment and large tires without flinching | |

|

Upper control arm mounts feature rebuildable Johnny Joints® for maximum suspension articulation with unsurpassed durability | |

|

Rock-proof Currie nodular iron front cover protects expensive internals, adds structural support to the housing's face flange, and locates the driver’s side upper control arm mount | |

|

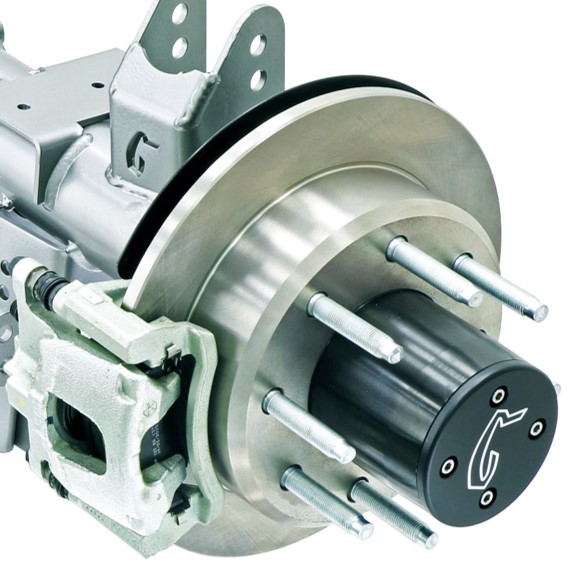

13-inch diameter vented rotors and dual-piston calipers provide the increased brake capacity required for stopping large tires | |

|

Warn® premium manual locking hubs are the industry standard for durability and reliability | |

Extreme 60 Rear Features

|

||

|

Desert race-inspired 2-inch heat-treated chromoly spindles and billet steel full-floating hubs carry the weight of the vehicle, eliminating the influence of side loading and impact shock on axle durability. Safety is improved as the wheel and brake remain in place and fully functional in the rare event of an axle failure | |

|

Currie Performance double splined full-floating heat-treated chromoly axles provide superior strength and durability over traditional flanged floater axles | |

|

Modified JK OEM backing plates and parking brake assemblies provide reliable operation with broad availability of serviceable wear items | |

|

Rock-proof Currie nodular iron cover protects expensive internals and adds structural support to the housing's face flange for increased rigidity | |

| Vehicle Fitment | 2020 and newer Jeep Gladiator (JT) truck |

| Extreme 60 | ___________________________________________________________________________________ |

| Housing | Extreme 60 Nodular Iron High-Clearance Center Section with Rotated Cover, Ring Gear Load Bolt and Integrated Skid Plate |

| Bearing Caps | Increased cross section nodular iron caps secured with ARP® fasteners |

| Pinion Oiling | High volume flow-thru recirculating oil system |

| Gear Set | Dana 60™ reverse rotation thick gear sets (compatible with super 60 reverse cut gears) |

| Differential Carrier | Only high speed differential carriers (designed for low numerical gears) are used, enabling the use of stronger thick ring gears for all gear ratios. Carrier outside diameter is turned down to 8.30 inches for load bolt clearance |

| Ring Gear Load Bolt | Eliminates ring gear deflection under heavy load (3/4"-16 right hand thread with Jam nut) |

| Pinion Yoke | 1350 u-joint |

| Skid Plate | AR400 hardened steel skid plate |

| Differential Cover | Currie nodular-iron cover, Red |

| Axle Tubes | 3 1/2 inch diameter, .375 wall DOM tube |

| Suspension Brackets | Heavy gauge 3/16 steel mounting brackets |

| Width | 70-inches wide (between wheel mounting surfaces) |

| Wheel Bolt Pattern | 8-lug (8 x 6.5 in.) with 9/16 studs |

| Finish | Black satin powder coat |

| Front Extreme 60 | ___________________________________________________________________________________ |

| Axles | Currie Performance 35-spline (1.5 in. diameter) 4340 Chromoly inner and outer axle shafts with 1480 u-joints |

| End Forgings | Currie 1-ton heavy-duty forged steel inner C’s |

| Steering Knuckles | Currie 1-ton nodular iron steering knuckles machined and keyed for high-steer arms |

| Unit Bearings | 1-ton unit bearings with JK tone rings installed for ABS and ESP retention |

| Hubs | Warn Premium locking 35-spline hubs |

| Brake Rotors | 13-inch vented rotors (over 1.1 in. larger diameter than stock, provides increased brake force) with zinc plated caliper brackets |

| Brake Calipers | F-350 Dual-piston calipers |

| Tie Rod | 1-ton 1.357 in. OD x .375 wall heat treated chromoly tube with forged tie rod ends |

| Control Arm Mounts | Johnny Joints® installed with ½” greasable bolts |

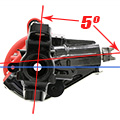

| Geometry | Optimized for vehicles with 3 to 4-inches of lift (5 degrees of pinion angle and 5 degrees of caster angle) |

| Trac Bar Mount | Integrated raised track bar and ram-assist mount. Trac bar mount height set for 3 to 4 inch lift, ram-assist mount setup for PSC 8-inch travel ram |

| Rear Extreme 60 | ___________________________________________________________________________________ |

| Axles | Currie Performance double splined full-floating (35-spline 1.5-inch diameter) 4340 heat-treated chromoly |

| Floater Spindle | Currie Performance 2.5-inch heat-treated 4140 Chromoly spindles, supports 35 or 40-spline axles |

| Floater Hub | Currie Performance billet full-floating hubs with 35-spline drive flanges, JK tone rings installed for ABS and ESP retention |

| Brake Rotors | 13.750-inch vented rotors |

| Brake Calipers | Retains the vehicle's factory calipers |

| Parking Brake | Modified Jeep Gladiator OEM backing plate and parking brake assembly |

| Geometry | Optimized for 4-inchs of lift with 5 degrees of pinion |

NOTES:

ABS Sensors: Does not include ABS sensors, the factory sensors from the stock axle must be retained and installed on the Extreme 60 housing

Computer Programming: 2012 and newer vehicles require a computer programmer to reset the gear ratio and tire height in the vehicle's computer for the proper function of the vehicles stability control and transmission shift points

Brake Upgrade: The big brake kit included with the Extreme 60 uses 13.25-inch rotors with dual-piston calipers to provide the stopping power required for 37-inch and larger tires

Wheel and Tire Size: 17-inch or larger wheels are required for proper clearance of the brake calipers. Maximum recommended tire size is 40-inches

Overall Width: Axle width is 70-inches (+4.6 inches over stock) between wheel mounting surfaces. Additional width improves turning angle with 37-inch and larger tires

Steering Stabilizer: The Extreme 60 Ram assist bracket requires an aftermarket stud style trac bar bolt to accommodate a steering stabilizer. Trac bar bolts are available from FOX Racing P/N 803-02-028 or Synergy Manufacturing P/N 8806-01

Differential Carriers: Carriers provided by Currie for the Extreme 60, are turned down to 8.300" O.D. for load bolt clearance. If a standard O.D. carrier is installed the load bolt will need to be backed out to prevent damage