Description

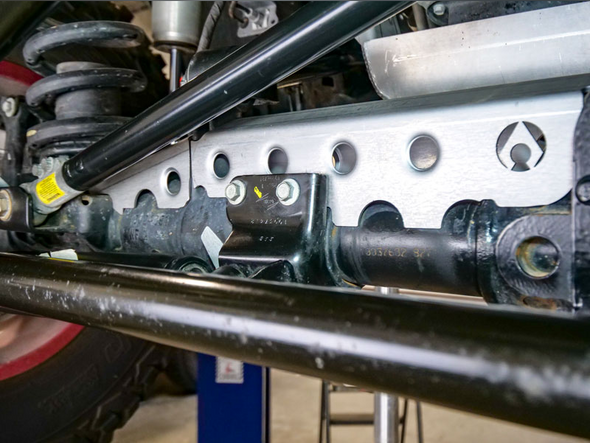

Artec Industries is excited to announce our new JL SHIELD. The NEW JEEP JL front axle now includes a new Center Axle Disconnect (CAD or Front Axle Disconnect FAD) system for improved fuel efficiency. This new inclusion on the axle features a very thin sheetmetal skid plate from the factory which is prone to bending and denting, not to mention being a rock magnet itself. Artec Industries is the FIRST COMPANY TO ADDRESS THIS VULNERABLE PART.

Our new JL SHIELD is constructed from HEAVY DUTY 1/4" thick steel...twice the thickness of the OEM skid plate. The new design also uses countersunk flat head bolts for improved smoothness on the bottom...meaning you'll have less edges to catch on rocks. To improve the smoothness, we've eliminated unnecessary edges and extended the leading edge to the front of the axle and included an angled flange to protect the axle and allow rocks to glide under. The JL SHIELD is fully welded and hard powdercoated for direct bolt-on installation and a long life. All this at a PHENOMENAL PRICE and manufactured in-house which means its MADE IN THE USA!

Features:

- First OEM Replacement on market for JL CAD/FAD skid plate

- Works on both JL Wranglers and JT Gladiators

- Heavy Duty 1/4" construction....twice the thickness of OEM skid plate

- Designed using original OEM files and CNC laser cut and CNC bent in-house for precise fit

- Uses Countersunk Flat head bolts for a smooth bottom...keeps rocks from catching on bolt heads*

- Leading edge of OEM skid is extended forward and has a bent flange to provide a smooth bottom with no edges for rocks to catch on

- Fully Welded and powdercoated for direct bolt-in installation...5 minute install

- MADE IN USA IN HOUSE FROM USA MATERIALS

NOTE: While all precautions are made to ensure the powdercoated surface is protected, small scratches from the shipping process may be present upon arrival.

*Flat head bolts provided just bottom two holes. Reuse OEM bolts on upper holes.